ABSOLUTE QUALITY

What it Means to us

To Eurotech, it means accuracy, integrity, dependability, tenaciousness and being unparalleled in the marketplace. Every stage counts.

Quality Requirements

Eurotech's success rests on our commitment to meet consumer requirements. We pride ourselves on delivering exceptional absolute quality in everything we do. Quality is at the core of our values, and it is our commitment to providing our customers with products and services that exceed their expectations. Since 2005 we have been accredited with ISO 9001:2015; ISO 14001:2015; & ISO 45001:2018.

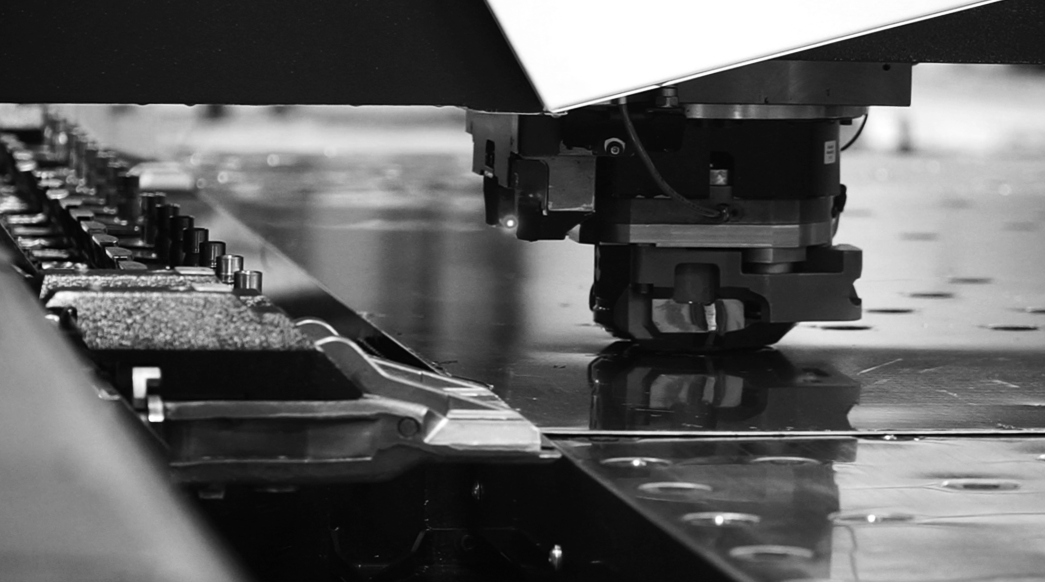

Raw Materials

At Eurotech, we prioritize excellence in manufacturing superior raw materials for uncompromising quality. Our products are crafted using absolute quality sheet metal such as Electro Galvanized (EG) sheets, Cold Rolled Close Annealed (CRCA) sheets, Galvanized (GI) sheets, Aluzinc sheets, Stainless Steel sheets, Copper sheets, and Polycarbonate sheets. We ensure top quality, durability, corrosion resistance, strength, and aesthetic appeal.

Software

Our cutting-edge technology hardware and software generates the highest quality and quickest results with CAD/CAM capabilities. 2D/3D likewise, with SolidWorks by Dassault Systèmes, can also be used for drawings dependent upon your preferences.

Where necessary, 3D animations are created to serve as tutorials for assemblers and speed up learning curves. Our programmers make sure to generate the lowest scrap percentage possible. Our production planning is always turned towards the shortest cycle time for each and every customer order.

Welding

At Eurotech, welding capabilities integrates cutting-edge MIG, TIG, Spot, Laser and Stud techniques for robust, precise, and heat-efficient welds across sheet metal products. With spot welding ensuring swift bonds and laser welding minimizing heat impact on our materials, our comprehensive approach, including stud welding for seamless sheet metal stud integration, embodies innovation. These streamlined techniques offers industries unparalleled strength, precision, and adaptability in our fabrication processes.

Powder Coating

Our spray pre-treatment procedure is divided into 7 operations: degreasing, overflow water rinsing 1, overflow water rinsing 2, DM water rinsing, Oxsilan® coating, water rinsing and DM water rinsing which is repeated.

Salt Spray Test

A salt spray test is performed to test the capacity of a product to withstand atmospheric conditions. In our industry, acceptable levels are 250 hours (scratched sample) and 400 hours (plain sample). At Eurotech

our products pass 2000 hours

which is equivalent to over 60 days of continuous high corrosive attack. Such a performance is unmatched in the market. This means our products can withstand any climatic condition and can be used anywhere in the world.